Характеристики

A2A (Clearance angle major Pos. A)

21 Degree

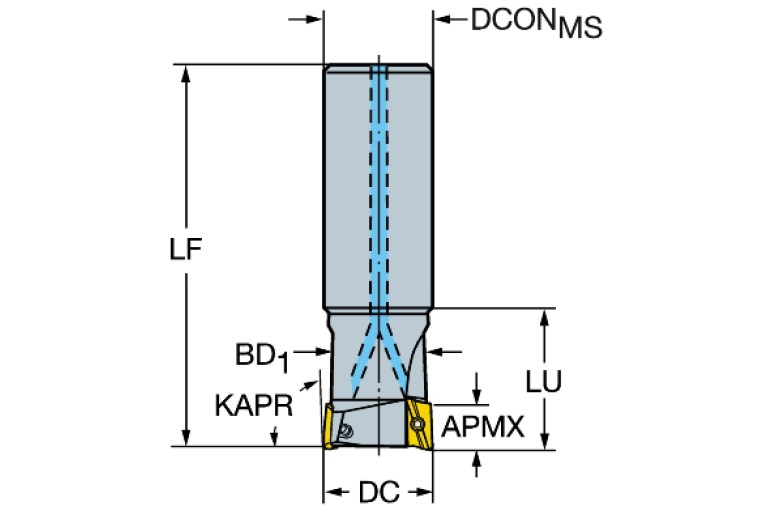

APMX (Depth of cut maximum)

10 mm

AZ (Plunge depth maximum)

1 mm

B1A (Cutting edge length Pos. A)

11.45 mm

B2A (Insert width Pos. A)

6.8 mm

B3A (Inscribed circle diameter Pos. A)

6.8 mm

BI (Block index)

1

BLDA (Tool style code Position A)

4

BMC (Body material code)

S - Solid steel

C1A (Insert thickness Pos. A)

3.59 mm

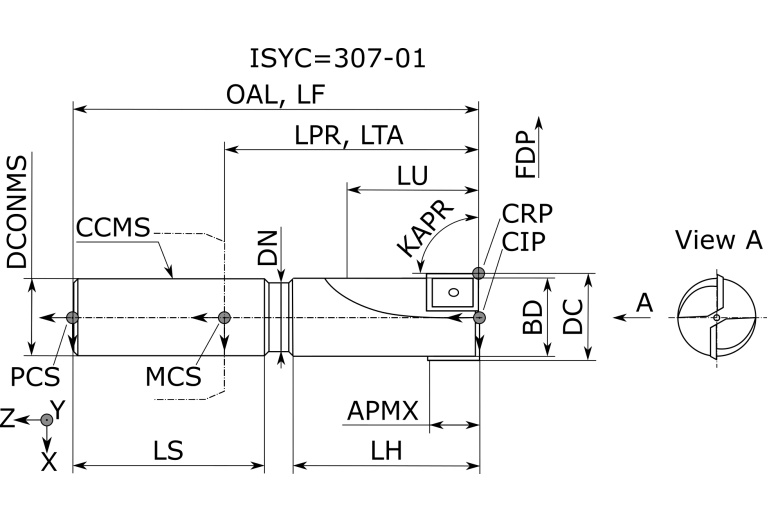

CCONMS (Connection count machine side)

2

CICT (Cutting item count)

4

CNSC (Coolant entry style code)

1 - With Coolant entry, axial concentric

CXSC (Coolant exit style code)

3 - With Coolant exit, axial and radial

CXSC (Coolant exit style code) / Тип подвода СОЖ

3 - With Coolant exit, axial and radial

DC (Cutting diameter)

25 mm

DCP (Data chip provision)

0 - Without data chip

Delivery state valid from

12/1/2023

DIN

ZYL02500115

F23 (Number of mounting layers)

1

F24 (Cutting item count per mounting layer)

4

GAMF (Rake angle radial)

17.06 Degree

GAMP (Rake angle axial)

-8.729 Degree

HAND (Cutting direction)

R - Right

Interface codes

J6 / J61

ISO

ZYL01G2500$$$$

KAPR (Tool cutting edge angle)

90 Degree

LF (Functional length)

120 mm

LOC-03 ISO

ZYL01G2500$$$$

LOC-03 (CCFMS Connection code form)

01

LOC-03 (CCSMS Connection code style)

5 Shaft in machine direction or hole in workpiece direction

LOC-03 (CCTMS Connection code type)

ZYL cylindrical shank

LOC-03 (CCUMS Connection code unit base)

1 Metric with coolant

LOC-03 (CZCMS Connection size code)

0250

LOC-03 (DCONMS Diameter)

25 mm

LOC-03-Connection-codes

J6 / J61 - connection code machine end

LOC-03-DIN

ZYL02500115

LPR (Protruding length)

64 mm

LS (Shank length)

88 mm

LU (Usable length)

32 mm

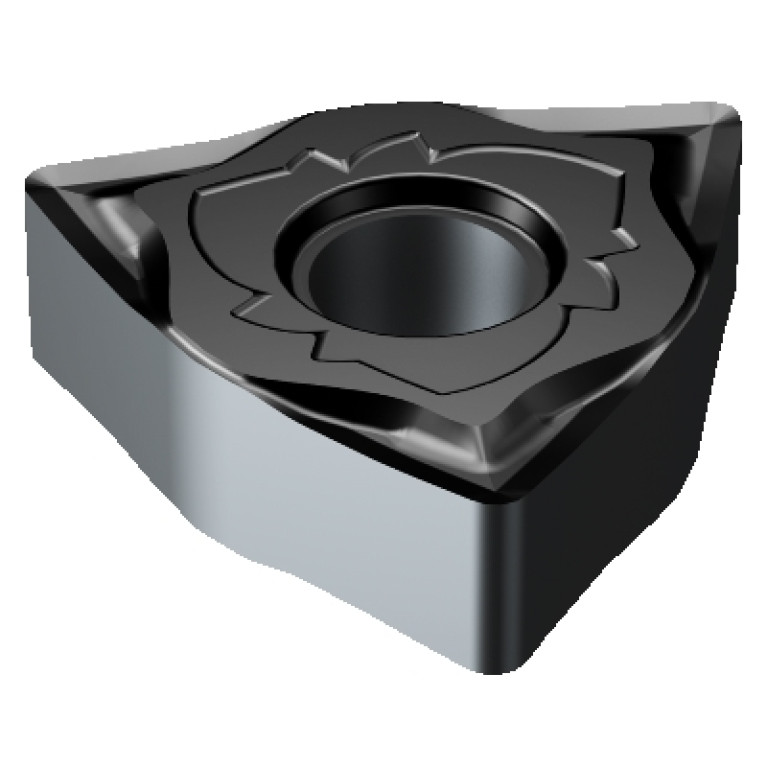

MIID (Master insert identification)

R390-11..

OAL (Overall length)

120 mm

RMPX (Ramping angle maximum)

5 Degree

RPMX (Rotational speed maximum)

36500 1/min

Working process

FEC - Square shoulder milling,FNB - Slotting,FNU - Groove milling,FPL - Face milling

WT (Weight of item)

0.401 kg

ZEFF (Face effective cutting edge count)

4

ZEFP (Peripheral effective cutting edge count)

4

Вы смотрели