Характеристики

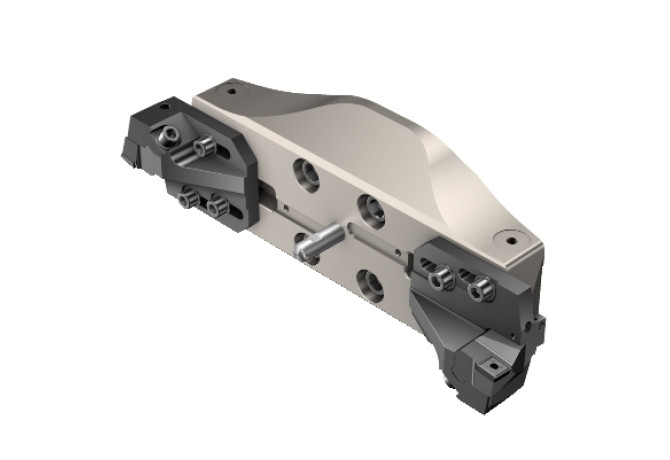

ADJBY (Adjustment property)

1 - Radial adjustment possible

ADJRGA (Adjustment range axial)

41 mm

BMC (Body material code)

L - Light alloy

CNSC (Coolant entry style code)

1 - With Coolant entry, axial concentric

CXSC (Coolant exit style code)

3 - With Coolant exit, axial and radial

CXSC (Coolant exit style code) / Тип подвода СОЖ

3 - With Coolant exit, axial and radial

DCN (Cutting diameter minimum)

458 mm

DCP (Data chip provision)

0 - Without data chip

DCX (Cutting diameter maximum)

540 mm

Delivery state valid from

12/1/2023

DIN

SPK10160213

DIN CSW1

SV-TM180600

HAND (Cutting direction)

R - Right

Interface codes

J6 / J61

Interface codes CSW1

J41 / J441

ISO

SPK02A1016$$$$

ISO CSW1

SV$$TM1806$$3**$$$$

KAPR (Tool cutting edge angle)

90 Degree

LF (Functional length)

124 mm

LOC-01 ISO

SV$$TM1806$$3**$$$$

LOC-01-Connection-codes

J41 / J441 - Interface code position A (cutting edge) (Unknown 01)

LOC-01-DIN

SV-TM180600

LOC-03 ISO

SPK02A1016$$$$

LOC-03 (CCFMS Connection code form)

02

LOC-03 (CCSMS Connection code style)

3 Hole pattern (through bore) machine side or hole pattern (threaded hole) machine side or

LOC-03 (CCTMS Connection code type)

SPK Spindle nose mounting

LOC-03 (CCUMS Connection code unit base)

1 Metric with coolant

LOC-03 (CZCMS Connection size code)

1016

LOC-03 (DCONMS Diameter)

40 mm

LOC-03-Connection-codes

J6 / J61 - connection code machine end

LOC-03-DIN

SPK10160213

LPR (Protruding length)

124 mm

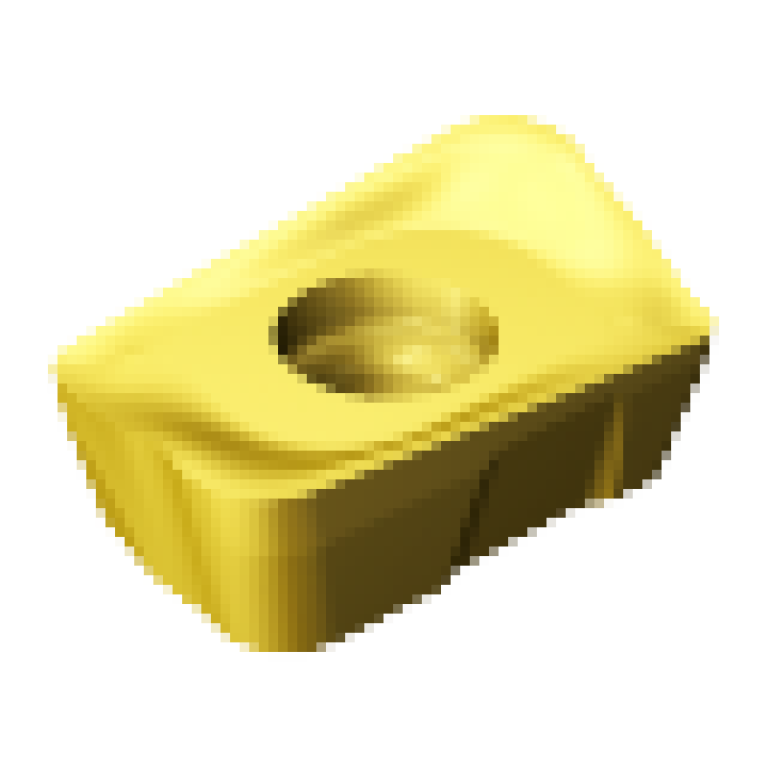

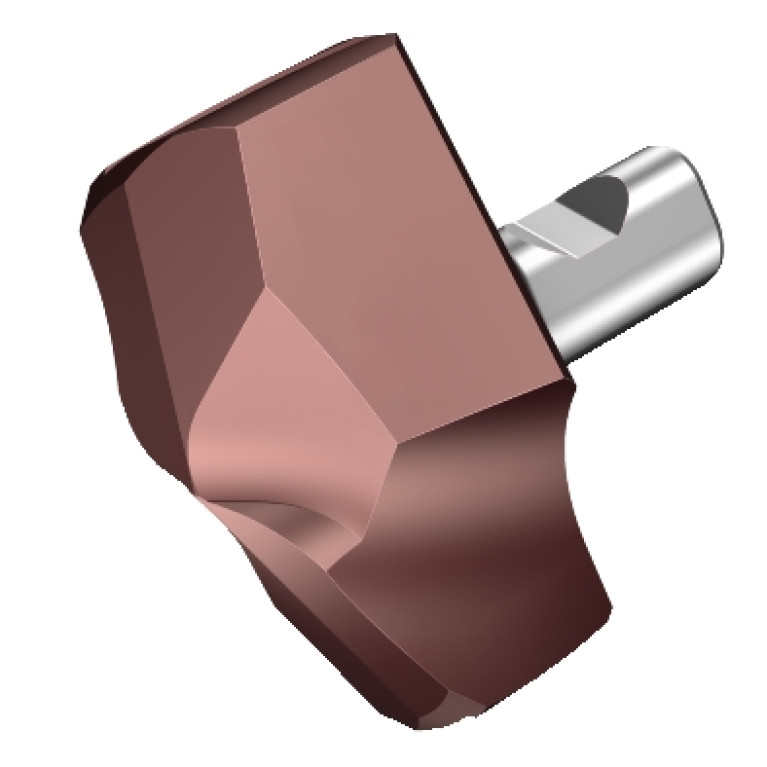

MIID (Master insert identification)

SPMT1810-BM

OAL (Overall length)

124 mm

RPMX (Rotational speed maximum)

834 1/min

Working process

BAB - Open by boring

WT (Weight of item)

16.741 kg

ZEFP (Peripheral effective cutting edge count)

2

Вы смотрели